If you are looking for the Best Battery Management System (BMS), then you’re in the right place. One thing is for sure, you can now get your own from the Orion BMS Lithium-Ion manufacturing company — at a very cost-effective and pocket-friendly price. Perse, anyone who owns an Electric Vehicle (EV) can tell you how important it is to know where your next charging point is.

More so, no matter where you are on the road. What’s more, it’s just as handy to know which points are most easily reachable and accessible from your home or place of work Having a strong understanding of this will do wonders in any ongoing battles with ‘range anxiety’ — the name given to the feeling of unease some EV drivers feel when they aren’t quite sure of things…

Suffice it to say, lack of surety as to when their next charging opportunity will present itself. Luckily for you, before talking more about the topic of the day, together with our partners, we’re yet on hand to provide road users with a full breakdown — where their nearest EV charging point is at all times. So, with much ado, below you’ll see the guide link to gather all the info.

Precisely, in this UK stats-driven guide, you’ll learn more about the topmost best points that are closest to your home. As well as along every step of any future journeys. In nutshell, it’s a complete list map of the best UK charging points. As well as everything else that a potential electric vehicle owner needs to know. Whereby, they cover a variety of stats and figures.

Resource Reference: Electric Car Charging Point Map Stats-Driven Guide

Globally, The number of publicly accessible chargers reached 1.8 million, an increase of 37% in 2021. Whereas, in the UK specifically, there are over 27.5k charging devices in the UK. Since 2015, public charging devices have grown by 43% year-on-year. This growth is only going faster. In fact, the government has set ambitious targets of introducing 145k new charging points every year from 2030 onwards. However, not all charging points are created equal.

In the UK, 56.7% of EV charging points are classed as fast, meaning they’ll fully charge a Tesla Model S in 5-11 hours. In October 2021, EVs held a 23.1% market share of all vehicles being registered in the UK — this is a sharp rise from April 2021, when it was just 13.3%. 22% of British drivers state that they are very likely to switch to electric vehicles in the future.

Their other key findings include:

- The rise in EV charging points in the UK

- How fast different charging points will charge your car

- The popularity of electric vehicles

- Consumer attitudes towards EVs

And now, with that in mind, let’s back to our business of the day…

What Is A Battery Management System (BMS)?

Simply put, Battery Management System (BMS) is the brains behind battery packs. They manage the output, charging, and discharging and provide notifications on the status of the battery pack. They also provide critical safeguards to protect the batteries from damage. Let’s take a look at a battery management system to familiarize ourselves with its components.

The single most important function that a battery management system performs is cell protection. Lithium-ion battery cells have two critical design issues; if you overcharge them you can damage them and cause overheating. And even explosion or flame so it’s important to have a battery management system to provide overvoltage protection.

In addition, Lithium-ion cells can also be damaged if they’re discharged below a certain threshold, approximately 5 percent of total capacity. If the cells are discharged below this threshold their capacity can become permanently reduced.

All in all, to ensure a battery’s charge doesn’t go above or below its limits, a battery management system has a safeguard device called a dedicated Lithium-ion protector. Every battery protection circuit has two electronic switches called “MOSFETs.” MOSFETs are semiconductors used to switch electronic signals on or off in a circuit.

What A Discharge MOSFET And A Charge MOSFET Entails

A battery management system typically has a Discharge MOSFET and a Charge MOSFET. If the protector detects that the voltage across the cells exceeds a certain limit, it will discontinue the charge by opening the Charge MOSFET chip. Once the charge has gone back down to a safe level then the switch will close again.

Similarly, when a cell drains to a certain voltage, the protector will cut off the discharge by opening the Discharge MOSFET. The second most important function performed by a battery management system is energy management. A good example of energy management is your laptop battery’s power meter. Most laptops today are not only able to tell certain aspects.

Resource Reference: All You Need To Know About Electric Vehicles In Detail

Considerably, such as how much charge is left in the battery but also what your rate of consumption is and how much time you’ll have left to use the device before the battery needs to be recharged. So, in practical terms, energy management is very important in portable electronic devices. But, wait a moment… What does a Battery Pack contain?

Usually, a battery pack consists of several individual cells working together. If they go out of balance, there’s stress on individual cells. Leading to premature charge termination and a reduction in the overall battery cycle life. The battery management system — battery cell balancers — extends its life by preventing this imbalance of charge in individual cells from occurring.

The Key Battery Management System (BMS) Features Plus Notable Solutions

By definition, the key to energy management is “Coulomb Counting.” For example, if you have 5 people in a room and 2 people leave you’re left with three if three more people enter you now have 6 people in the room. If the room has a capacity of 10 people, with 6 people inside it’s 60% full. A battery management system tracks this capacity.

This state of charge is communicated to the user electronically through a digital bus called an SM BUS or through a state of charge display where you press a button and an LED display gives you an indication of the total charge in 20% increments. Battery management systems for certain applications also include an embedded charger consisting of a control device.

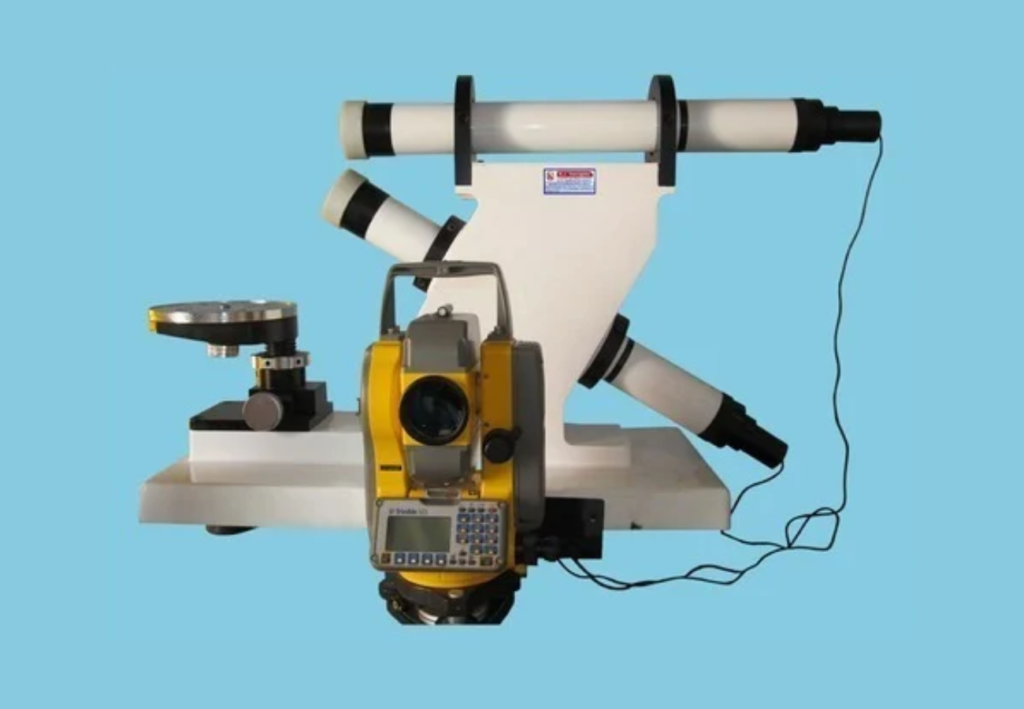

A good example is such as the one for this hand-held point-of-sales terminal shown in the illustration image above. Not forgetting, an inductor (which is an energy storage device), and a discharger. After all, the control device manages the charging algorithm. For lithium-ion cells, the ideal charging algorithm is constantly current and constant voltage.

1. Battery-Powered Electric Vehicles (BEVs)

To enumerate, Battery Electric Vehicles (BEVs), or as frequently called EVs, are fully-electric vehicles with rechargeable batteries and no gasoline engine. Battery electric vehicles store electricity onboard with high-capacity battery packs. Surprisingly, BEVs do not emit any harmful emissions and hazards caused by traditional gasoline-powered vehicles.

A recent study shows that in the first half of 2022, the number of new battery electric vehicles (BEVs) and plug-in hybrid electric vehicles (PHEVs) reached 4.3 million. Electric Vehicle (EV) chargers are classified according to the speed with which they recharge an EVs battery. For your information, the classifications are Level 1, Level 2, and Level 3 or DC fast charging.

Level 1 EV charging uses a standard household (120v) outlet to plug into the electric vehicle and takes over 8 hours to charge an EV for approximately 75-80 miles.

Important to realize, level 1 chargers (workplace/home-based) have the capability to charge most EVs on the market. While level 2 charging requires a specialized station that provides power at 240v. Then again, level 2 chargers are typically found at workplaces and public charging stations. And will take about 4 hours to charge a battery to 75-80 miles of range.

Level 3 charging, DC fast charging, or simply fast charging is currently the fastest charging solution in the EV market. As of today, there are quite a number of various BEVs plus manufacturer examples that can charge on DC Level 3 Fast Chargers. Below is a list of the topmost manufacturers of battery electric vehicles in the industry.

|

|

2. Plug-in Hybrid Electric Vehicle (PHEV)

A Plug-in Hybrid Electric Vehicle or a PHEV like Chevy Volt can recharge the battery through both regenerative braking and “plugging in” to an external source of electrical power. While “standard” hybrids can (at low speed) go about 1-2 miles before the gasoline engine turns on, PHEV models can go anywhere from 10-40 miles before their gas engines provide assistance.

Below Are Other PHEV Examples

|

|

3. Hybrid Electric Vehicles (HEVs)

On one hand, HEVs are powered by both gasoline and electricity. The electric energy is generated by the car’s own braking system to recharge the battery. In general terms, this is what most professional electricians will call ‘regenerative braking.’ Bear in mind, that regenerative braking is a process where the electric motor helps to slow the vehicle.

And while doing so, it uses some of the energy normally converted to heat by the brakes. On the other hand, HEVs start off using the electric motor, then the gasoline engine cuts in as load or speed rises. Some of the most common Hybrid Electric Vehicles (HEVs) include Toyota Prius Hybrid, Honda Civic Hybrid, Toyota Camry Hybrid, etc.

Eventually, it’s extremely simple to charge your electric vehicle at an EVgo station. There are 3 different ways to charge your car quickly and easily. For example, you can use an app, your RFID card, or a credit card. Learn everything about charging an Electric Vehicle in detail. Including how to charge, charging time, charging cost, and driving range on a single charge.

Go For An Orion BMS 2 Lithium-Ion Battery Management Systems

First of all, the Battery Management System (V2) features of the Orion Lithium-Ion Standard Battery Systems — by the Orion BMS Company — have high immunity to harsh EMI (electrical noise) and voltage transients. Especially, found in automotive environments that plague other BMS systems. Secondly, the Orion li-ion BMS is a full-featured lithium-ion battery.

Inclusive of a battery management system that is specifically designed to meet the tough requirements. Particularly, protecting and managing battery packs for the likes of electric vehicles (EV), plug-in hybrid (PHEV), and hybrid vehicles (HEV) with automotive-grade quality. In addition to automotive uses in electric and hybrid vehicles, it has even other added features.

With that in mind, you can check out the Complete Orion 2 Change Log Document that has more details. Or, otherwise, go ahead and Shop For Orion BMS Online to get your very own Orion-based BMS Battery and other management system tools.

Why Orion BMS Lithium-ion Battery System?

- Its centralized design provides high EMI and noise immunity.

- Capable of measuring up to 180 battery cells per unit connected in series based on configuration.

- It performs intelligent cell balancing (passive) with configurations available in increments of 12 cells in series.

- Calculates state of charge (SOC) and uses professional automotive-grade locking connectors.

- Calculates discharge current limit (DCL) and charge current limit (CCL).

Chiefly, it can also measure cell voltages between 0.5v and 5.0v. With dual (x2) CANBUS 2.0B interfaces which are fully programmable. That said, you can have a look at the Full Product Specification Sheet (PDF) to learn more. Or rather, check out the full features list for more details plus other OBD2 diagnostic protocol support resources.

Here are the quick Specifications to note:

- Capable of measuring up to 180 battery cells per unit connected in series based on configuration.

- Up to 2x Remote Cell Tap Expansion Modules can be connected

- These key modules measure higher voltage battery packs (up to 800vDC max).

- Configurations are available in increments of 12 cells in series.

- The centralized design provides high EMI and noise immunity.

- Performs intelligent cell balancing (passive).

- Calculates state of charge (SOC).

- Uses professional automotive-grade locking connectors.

- Calculates discharge current limit (DCL) and charge current limit (CCL).

- Can measure cell voltages between 0.5v and 5.0v.

- Dual (x2) CANBUS 2.0B interfaces (fully programmable).

- OBD2 diagnostic protocol support.

- See the full features list

Equally important, the Orion BMS can also be used in stationary installations such as solar or wind storage batteries and UPS systems. Basically, there are three main types of electric vehicles (EVs), classed by the degree that electricity is used as their energy source. BEVs, or battery electric vehicles, PHEVs of plug-in hybrid electric vehicles, and HEVs vehicles.

So far, it’s important to realize, that only BEVs are capable of charging on a level 3, DC fast charge. Before you go for the likes of Orion BMS Lithium-Ion Battery Management System, there are some key functions of the Battery Management System you need to know about. In general, the battery management system should achieve the following functions:

A. Accurate SOC Estimation

As an example, estimate accurately the State of Charge (SOC) of the power battery pack. That is, the remaining battery power. In reality, ensuring that SOC is maintained within a reasonable range, prevents damage to the battery itself due to overcharging or over-discharge. Remarkably, displaying the power energy remaining in the hybrid electric vehicle battery at any time. Of course, referring to the charging state of the energy storage battery.

B. Dynamic Battery Monitoring

In the process of battery charging and discharging, the terminal voltage and temperature of each battery, charging and discharging current and total voltage of the battery pack are collected in real-time to prevent overcharging or over-discharging. At the same time, it also can show the status of batteries, select the batteries with problems, maintain the reliability and efficiency of the whole battery operation, and make the realization of the residual power estimation model possible.

C. No Overcharging/Over-Discharging

By the same token, the charging and discharging process of batteries usually utilizes current sensors. In particular, with higher accuracy and better stability for real-time detection. Generally, according to the different front-end currents of BMS, the corresponding sensor ranges are chosen to approach.

D. Quality Balance Among Batteries

Above all, balance technology is a key technology of the battery energy management system of all. FIC, as a design manufacturer for over 40 years, has the profound capability to design and produce a battery management system for your project. That said, it’s time that you now go ahead and Purchase An Orion Li-Ion Battery Management System for yourself.

The New Orion BMS 2 Major Improvements:

Significantly, there’s now a much smaller enclosure size for 24-72 cell configurations. Roughly, the new improvement has now a 40% lower weight on all models. In particular, due to the new enclosure design and streamlined (removable) heatsink. Minimum heat dissipation requirements apply.

Considerably, the new boosts in measurement accuracy and processor speed allow for more advanced calculations and logic. Plus a very new Status LED on the unit to indicate power status and the presence of faults. In addition to direct hardware support for several popular charging protocols. Including hardware support for SAE J1772 (directly interfacing with the pilot/proximity lines) and CHAdeMO for DC fast charging.

Remarkably, there’s also a much wider input power voltage range (now 12v-24vDC compatible) for better support on heavy vehicles and equipment. The Orion 2 BMS remains fully compatible with 12v applications. With the ability to directly drive certain contactors on select inputs (bypassing the need for intermediate signal relays in some situations) – see supporting documentation for details.

Not forgetting, there’s also a completely redesigned multi-unit series configuration (now using Remote Cell Tap Expansion Modules). This greatly simplifies connecting multiple units together in series and improves overall reliability. Plus yet another key additional feature of 2x new Multi-Purpose Output pins with programmable functions.

Last but not least, there are also significant algorithm and software enhancements to improve overall system accuracy. Particularly, for parameters such as the State of Charge and pack health.

NOTE: Must be remembered, that The Orion BMS is designed and manufactured by Ewert Energy Systems, Inc just in case you didn’t know. Of course, which is a research & development company focusing on developing solutions for plug-in hybrid and electric vehicles. Ewert Energy provides custom solutions as well as off-the-shelf components.

Summary Notes:

On one side, for all other Orion product manuals and other documentation, please visit their page on Downloads & Resources to gather more info. While, on the other side, for any quick/urgent help resolving common issues and problems, please see their Troubleshooting Guide which has more details — send a data snapshot and your battery profile with your email.

Other Related Resource References:

- What Is An EV (Electric Vehicle)? — TWI Global

- Original Orion BMS To Orion BMS 2 Migration Guide

- Explaining Electric & Plug-In Hybrid Electric Vehicles

- Types Of Electric Vehicles: BEVs, PHEVs, HEVs – EVgo

- How Do Electric Cars Work? | Electric Engines Explained — EDF

- The #20 Topmost Electric Cars By Top Gear’s Rank

Be that as it may, we hope you have gathered enough information in regard to the above-revised profile. But, just in case you’ll need more help, please feel free to Contact Us and let us know. Furthermore, our team of Web Tech Experts Taskforce will be more than glad to assist you. Likewise, you can also Submit A Request to the Orion BMS team for support.

Equally important, you’re welcome to share any other additional information, suggestions, opinions, recommendations, or even contribution questions (for FAQ Answers) in our comments section. Please go ahead and share the good read with all your online audience and social media followers. You’re also welcome to Donate to motivate us and support what we do.